- No products in the cart.

Collets Supplier & Distributor in USA

Frequently Asked Questions

1. What is the meaning of a collet?

A collet is a precision clamping device used in CNC machines to hold tools such as drills, end mills, taps, and reamers. It grips the tool tightly when squeezed by a collet nut or tool holder, ensuring accuracy and stability during machining. As a precision tool supplier in the USA, PAC Precision Tools offers a variety of collet types for different CNC applications.

2. What are the two main types of collets?

The two most common types of collets are workholding collets (used to hold a workpiece in lathes) and toolholding collets (used to hold cutting tools in CNC machines). Toolholding collets like ER, TG, and SK are used for high-precision machining, while 5C collets are widely used for workholding in turning operations.

3. What causes a collet to break?

Collets break due to over-tightening, using damaged or worn collets, inserting tools with incorrect shank sizes, or allowing chips and dirt to build up inside the holder. Excessive force or poor maintenance can cause cracks that lead to collet failure. Regular cleaning and proper torque settings help prevent damage.

4. What is the difference between ER, TG, DA, SK, and 5C collets?

ER collets offer the widest clamping range and are used for versatile toolholding. TG collets provide a stronger grip for heavy cutting. DA collets are older and used for light operations. SK (super collets) provide high precision and excellent runout control. 5C collets are mainly used for workholding rather than toolholding. PAC Precision Tools USA - a CNC tools distributor in the USA - supplies all major collet types.

5. How often should collets be replaced?

Collets should be replaced when they show signs of wear, cracking, or loss of clamping accuracy. Frequent use, high-speed machining, or dirty conditions can shorten their life. Most machinists replace collets every 3–6 months for optimal precision, depending on usage.

6. Can collets be used for tapping operations?

Yes, special collets like ER tap collets or quick-change tap collets are designed for tapping. They offer better torque transfer and protect taps from breaking. These collets are widely used in CNC tapping applications for improved accuracy.

7. Why is collet runout important in CNC machining?

Runout affects tool accuracy, surface finish, and tool life. Lower runout means the tool rotates more accurately, producing cleaner cuts and reducing vibration. High runout can damage tools and reduce machining quality, especially in precision cutting operations.

8. Why do collets lose grip over time?

Collets lose grip due to wear, dirt buildup, or excessive tightening. Over time, the spring steel weakens, reducing clamping force. Regular cleaning and proper torque settings help maintain performance and prevent premature wear.

9. Do different collet types require different nuts?

Yes, ER, TG, DA, SK, and other collet types all use specific collet nuts designed for their geometry. Using the wrong nut can lead to poor clamping and higher runout. Always match the nut to the collet system.

10. Need expert help choosing the right collet?

For more information, you can contact us here +1 262-282-2456 or email us at sales@pactoolsusa.com. We can recommend the best collet type for your CNC machine, material, and cutting conditions.

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

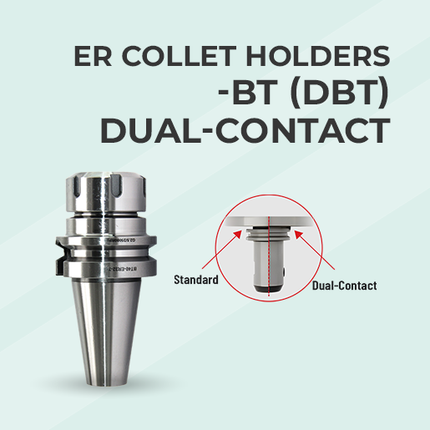

- ER Collet Holders-BT Taper

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

- Shrink Fit Holder-CAT(DCAT)Dual-contact

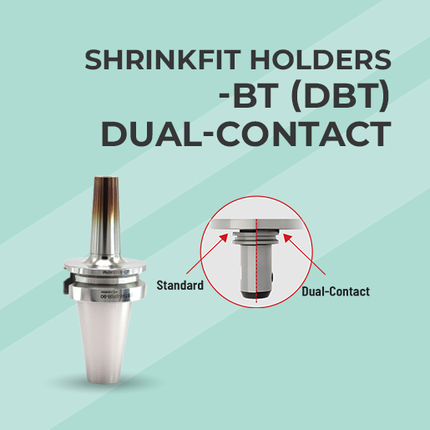

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

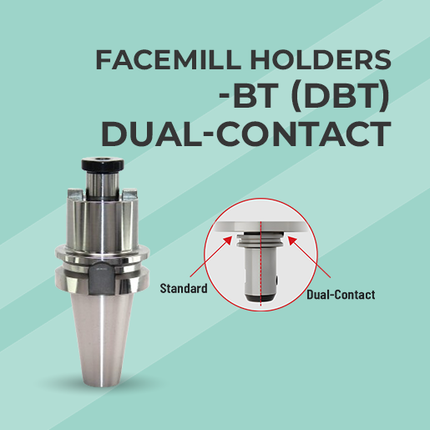

- Face Mill Holders-BT Taper

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

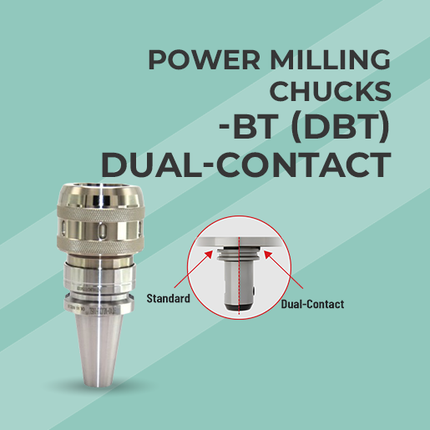

- Power Milling Holders

- Power Milling Holders-CAT Taper

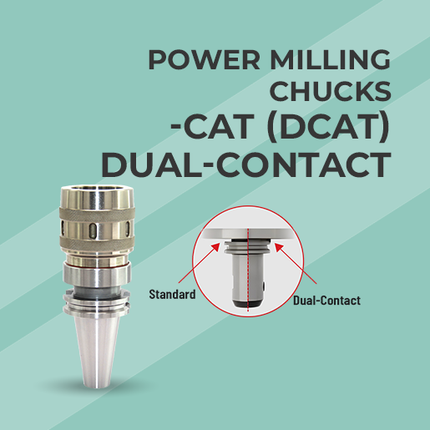

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube