- No products in the cart.

Retention Knobs Supplier & Distributor in USA

Frequently Asked Questions

1. What are Retention Knobs, and what is their purpose in CNC machining?

Retention Knobs, also known as pull studs, connect the tool holder to the CNC machine spindle. They allow the drawbar to securely clamp the tool holder during machining. PAC Precision Tools, a trusted Retention Knob supplier in USA provides knobs designed for safe and stable CNC operations.

2. How do I choose the correct size and type of Retention Knob for my tool holder?

The correct retention knob depends on the spindle type, tool holder standard (CAT, BT, or others), thread size, and gauge length. Using the correct specification ensures proper clamping force and spindle safety. PAC Precision Tools, a precision tools supplier in the USA can help verify compatibility.

3. What is the difference between Retention Knobs for hydraulic and mechanical tool holders?

Hydraulic tool holders may require specific retention knobs with precise gauge length and smooth surface finish. Mechanical holders use standard retention knobs but still require correct sizing. Using the wrong type can affect clamping and tool accuracy.

4. What standards or certifications should I look for when purchasing Retention Knobs?

Look for retention knobs manufactured to recognized standards such as DIN or ISO specifications. Certified heat treatment and material quality ensure strength and long service life. PAC Precision Tools, a CNC tools distributor in the USA typically supplies standard-compliant products.

5. How do Retention Knobs impact tool runout and spindle accuracy?

Properly manufactured retention knobs ensure correct tool holder seating in the spindle. Incorrect or worn knobs can cause misalignment, increased runout, and spindle wear. High-quality knobs help maintain machining accuracy.

6. Need help selecting Retention Knobs for your CNC machine?

For more information, you can contact us here at +1 262-282-2456 or email us at sales@pactoolsusa.com. PAC Precision Tools USA is a trusted CNC tools distributor in the USA and a precision tools supplier in the USA.

7. When should Retention Knobs be replaced?

They should be replaced if threads are worn, the head shows deformation, or after extended service cycles. Regular replacement helps prevent unexpected tool failure. PAC Precision Tools USA is a trusted CNC tools distributor in the USA and a precision tools supplier in the USA.

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

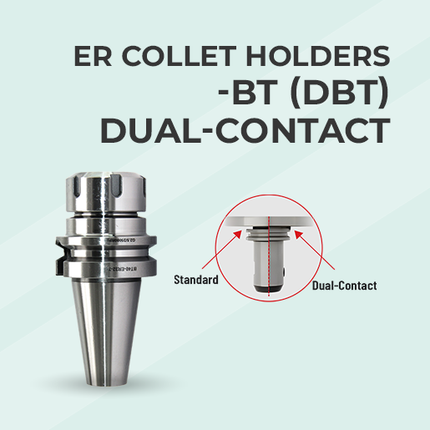

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

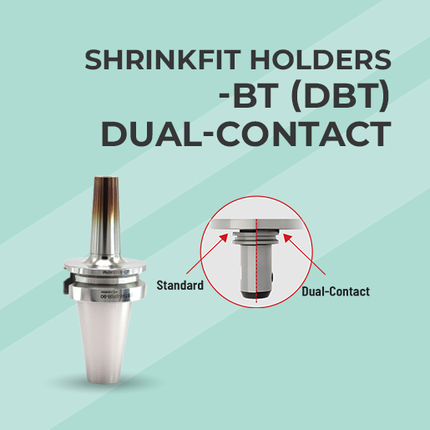

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

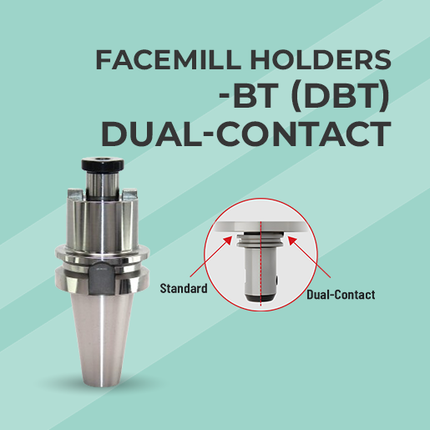

- Face Mill Holders-CAT(DCAT)Dual-contact

- Face Mill Holders-BT Taper

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

- Power Milling Holders

- Power Milling Holders-CAT Taper

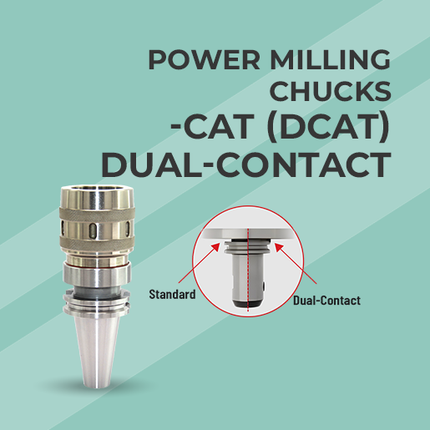

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

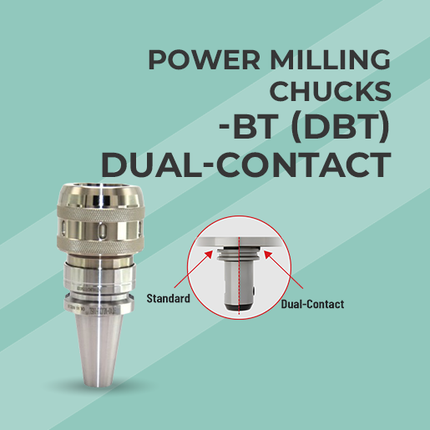

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube