- No products in the cart.

CNC Live & Dead Centers Supplier & Distributor in USA

Frequently Asked Questions

1. What is a Live Center and why is it used?

Explore more on pactoolsusa.com — A live center is mounted in the tailstock and contains bearings, allowing the tip to rotate along with the workpiece. This reduces friction and enables smoother machining at high RPMs.

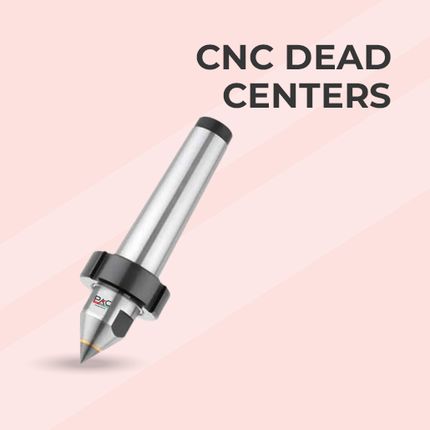

2. What is a Dead Center and what is its function?

Discover details on pactoolsusa.com — A dead center is fixed (non-rotating) and supports the workpiece in the spindle or tailstock. It offers excellent rigidity, making it ideal for precision operations like grinding.

3. What are the major differences between Live and Dead Centers?

Comparison info at pactoolsusa.com — Live centers have internal bearings, which prevent overheating and improve surface finish, though performance depends on bearing quality. Dead centers have no moving parts, so they offer higher rigidity but require proper lubrication.

4. When should you use a Live Center vs. a Dead Center?

See use cases at pactoolsusa.com — Use a Live Center for high-speed CNC turning or when supporting long, slender shafts.

Use a Dead Center for grinding, high-rigidity applications, or centering operations that require minimal movement.

Use a Dead Center for grinding, high-rigidity applications, or centering operations that require minimal movement.

5. What types of Live Centers are available?

View live center types on pactoolsusa.com — Live centers come in various types including standard, heavy-duty, bull-nose (for pipes and tubes), and spring-loaded versions (which compensate for thermal expansion).

6. What variants of Dead Centers are available?

See dead center options at pactoolsusa.com — Dead centers are available in full and half types. Half centers are useful for facing operations where full tool access to the end of the workpiece is required. Carbide-tipped versions are popular for wear resistance.

7. What are the maintenance tips for Live and Dead Centers?

Maintenance guide on pactoolsusa.com — Live Centers: Regularly inspect bearings, lubricate as needed, and check for runout to ensure accuracy.

Dead Centers: Lubricate to reduce friction; if wear rings or grooves appear, regrind or replace the center.

Dead Centers: Lubricate to reduce friction; if wear rings or grooves appear, regrind or replace the center.

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

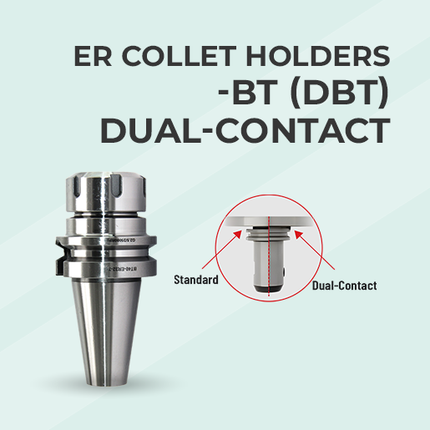

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

- Shrink Fit Holder-CAT(DCAT)Dual-contact

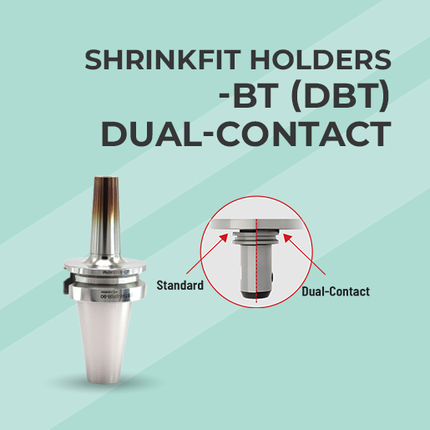

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

- Face Mill Holders-BT Taper

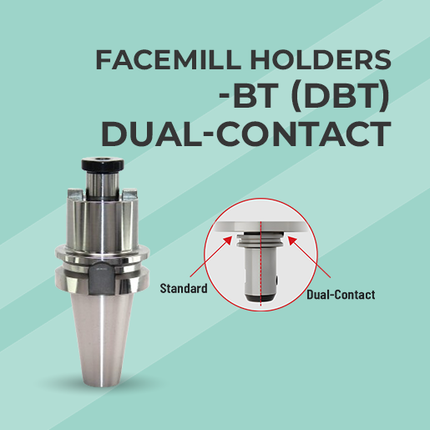

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

- Power Milling Holders

- Power Milling Holders-CAT Taper

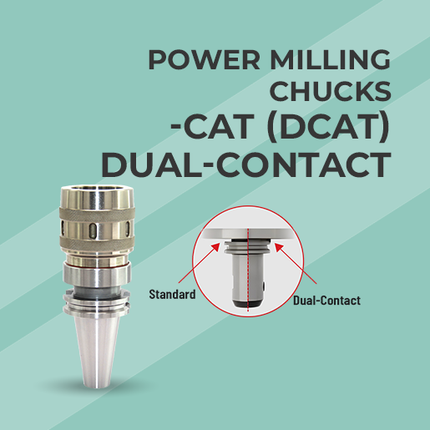

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

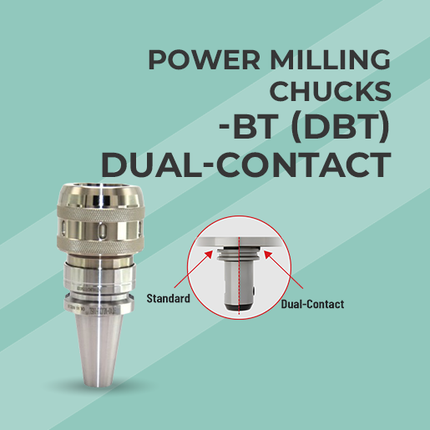

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube