- No products in the cart.

End Mill Holders Supplier & Distributor in USA

Frequently Asked Questions

1. What is an End Mill Holder?

An End Mill Holder is a tool for securely clamping a cutting tool, like an end mill, into a milling machine spindle to prevent it from rotating during use. These holders provide a more rigid and stable connection than a standard collet, especially for heavy-duty applications, by using a set screw to grip a flat, known as a Weldon shank, on the end mill’s body.

2. What are the benefits of using PACTools End Mill Holders?

End Mill Holders provide excellent rigidity, reliable performance, and reduced tool slippage and vibrations. They are ideal for demanding machining operations where strength and stability are essential for maintaining precision, dimensional accuracy, and surface quality.

3. How is an End Mill Holder different from an ER Collet Holder?

An end mill holder uses a set screw to push against the tool shank, which is less rigid and more prone to runout than an ER collet holder, making it suitable for less demanding applications. An ER collet holder uses a collet with a conical shape to grip the tool shank with high accuracy and a more rigid, vibration-damping grip, making it better for general-purpose and high-speed machining. End Mill Holders are better for high-torque applications, while ER Collet Holders are more versatile for lighter and varied tool sizes.

4. What sizes are available for End Mill Holders?

PAC Precision Tools offers End Mill Holders in multiple taper configurations, such as CAT, BT, and HSK, to fit a wide range of CNC spindles. Each size ensures precision fit, excellent balance, and compatibility with standard tool shank diameters used in machining. And the available project length is from 1-3/4", 2", 2-3/8", 2-1/2", and more. For more info, please contact us.

5. Are End Mill Holders suitable for high-speed machining?

Yes, PAC Precision Tools End Mill Holders can be suitable for high-speed machining, but it depends on the specific holder type and its quality. While traditional solid end mill holders are not recommended for high-speed machining operations due to their lack of balance, more advanced and precise holders like collet chucks, hydraulic holders(chucks), of those with high-speed tapers like HSK are well-suited for high-RPM operations

6. How should I maintain End Mill Holders?

Clean the holders after every use, remove metal chips and coolant residue, and lightly oil the surface to prevent rust. Proper care maintains accuracy, improves performance, and extends the lifespan of both the holder and the spindle. For more guidance on maintenance, you can email us at sales@pactoolsusa.com.

7.Do End Mill Holders support coolant-through systems?

Yes, selected models feature coolant-through capability that allows coolant to flow directly to the cutting area. This feature improves chip removal, tool life, and overall machining efficiency, especially during high-speed or deep-cutting operations

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

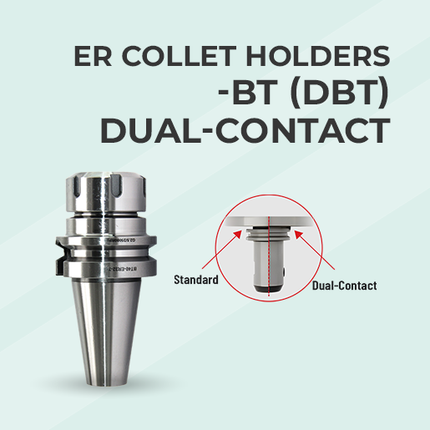

- ER Collet Holders-BT Taper

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

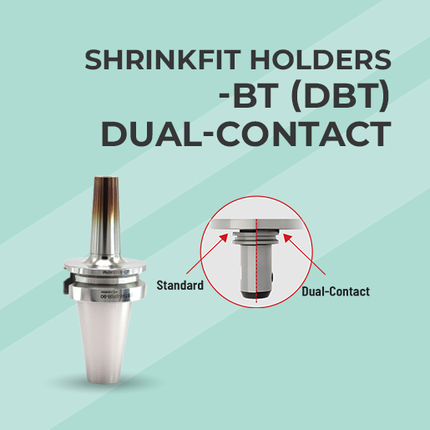

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

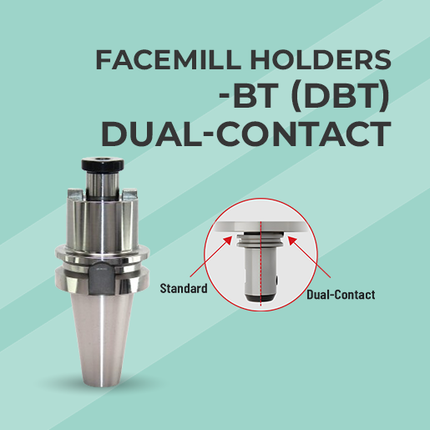

- Face Mill Holders-BT Taper

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

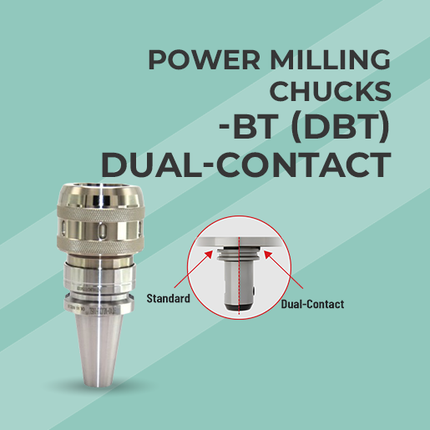

- Power Milling Holders

- Power Milling Holders-CAT Taper

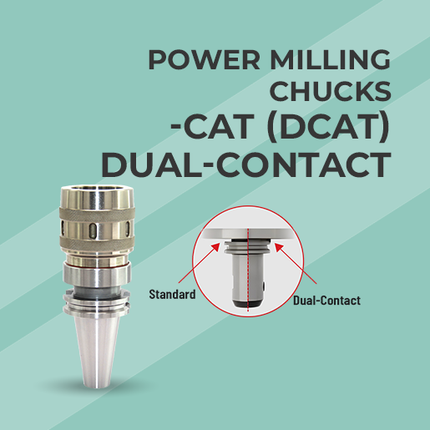

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube