- No products in the cart.

Hydraulic Holders Supplier & Distributor in USA

Frequently Asked Questions

1. What is a Hydraulic Holder?

A Hydraulic Holder is a precision tool holder that uses hydraulic pressure to clamp cutting tools securely. It offers excellent vibration damping, high accuracy, and strong gripping force, making it ideal for finishing and precision machining. As a precision tools supplier in the USA, PAC Precision Tools provides high-performance hydraulic holders.

2. Why are Hydraulic Holders used in CNC machining?

Hydraulic holders reduce vibration, improve surface finish, and offer consistent clamping without damaging the tool shank. They are commonly used for reaming, drilling, and finishing operations requiring tight tolerances.

3. Are Hydraulic Holders suitable for high-speed machining?

Yes, hydraulic holders are designed for smooth and stable operation at higher speeds. Their excellent balance and damping ability help reduce chatter and improve tool life during continuous machining.

4. What tool shank types fit into Hydraulic Holders?

They are designed for cylindrical shank cutting tools that meet h6 tolerance requirements. These holders provide uniform clamping, ensuring maximum accuracy and repeatability in demanding CNC applications.

5. How do I maintain a Hydraulic Holder?

Clean the clamping bore regularly, check for leaks, and store holders in a dry environment. Proper maintenance ensures long-term hydraulic performance and prevents accuracy loss.

6. What industries commonly use Hydraulic Holders?

Hydraulic holders are widely used in aerospace, automotive, mold making, medical machining, and general precision manufacturing because of their stability and accuracy.

7. Need help choosing the right Hydraulic Holder?

If you need more information and guidance in choosing the right Hydraulic Holder for your machining operations, you can contact us here +1 262-282-2456 or email us at sales@pactoolsusa.com. PAC Precision Tools USA is a trusted CNC tools distributor in the USA.

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

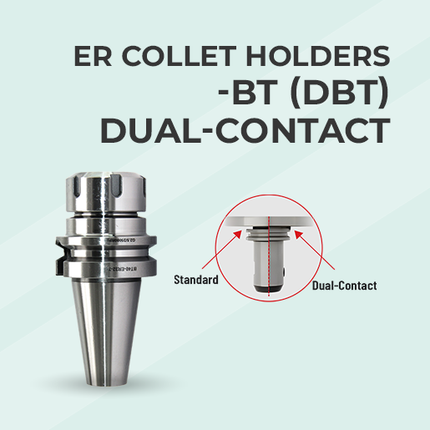

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

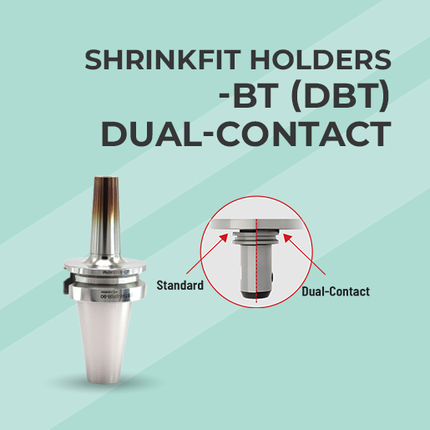

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

- Face Mill Holders-BT Taper

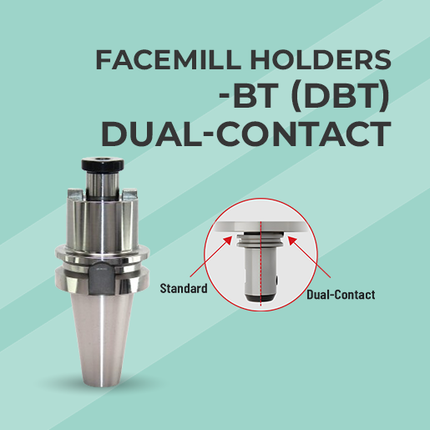

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

- Power Milling Holders

- Power Milling Holders-CAT Taper

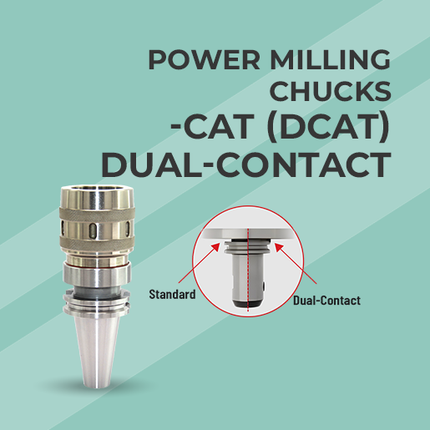

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

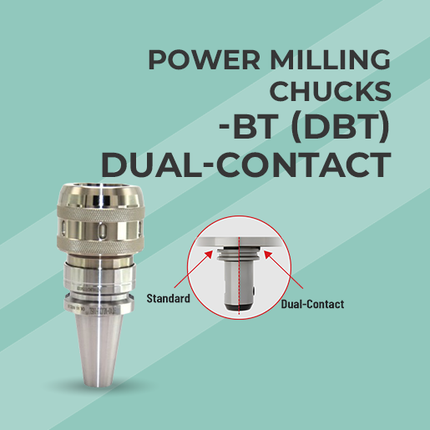

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube