- No products in the cart.

Collets

Frequently Asked Questions

1. What is a collet and what is its purpose?

You can explore options at pactoolsusa.com — A collet is a cylindrical, slotted sleeve that securely grips a cutting tool or workpiece. It ensures concentricity, low runout, and vibration-free machining in tool holding systems.

2. What are ER collets, and why are they commonly used?

For more information, visit pactoolsusa.com — ER collets (ranging from ER8 to ER50) are the most versatile type, capable of holding a wide range of shank sizes. They offer a wide clamping range and are ideal for high-speed machining and coolant-through applications.

3. What torque should be applied when tightening collets?

Recommended torque charts are available at pactoolsusa.com — Over-tightening can damage collets. Each size has a specific recommended torque—for example, ER32 typically requires 100–130 Nm. Using a torque wrench is considered best practice.

4. When should collets be replaced?

Check out guidelines at pactoolsusa.com — Collets should generally be replaced every 400–600 hours of use. If you notice visible wear, cracks, or excessive runout, they should be replaced sooner.

5. What is a coolant-through collet?

Learn more at pactoolsusa.com — Coolant-through collets are designed to allow internal coolant flow, improving chip evacuation and tool cooling—especially beneficial for deep-hole drilling operations.

6. How do you ensure compatibility between collet and chuck?

Find compatibility info on pactoolsusa.com — Always match the ER size of the collet and chuck. For example, an ER32 collet must be used with an ER32 chuck. Mismatched sizes can lead to loss of accuracy and poor tool holding.

7. What types of collets are available at PAC?

View full selection at pactoolsusa.com — PAC offers a wide variety of collet types including ER, TG, DA, R8, and 5C—manufactured using industrial-grade materials with high-precision standards.

8. How should collets be properly cleaned?

Cleaning tips available at pactoolsusa.com — Clean collets regularly using compressed air or a mild solvent. Built-up chips, dust, or oil can affect both clamping force and runout performance.

Quick Link

- Tool Holders

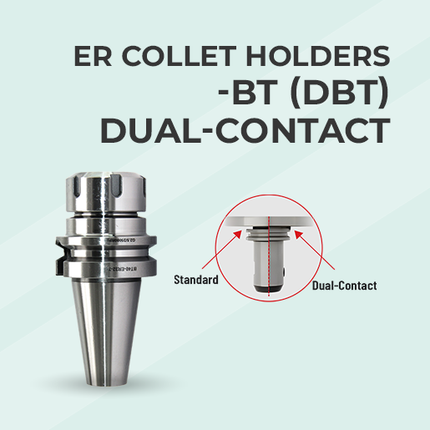

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

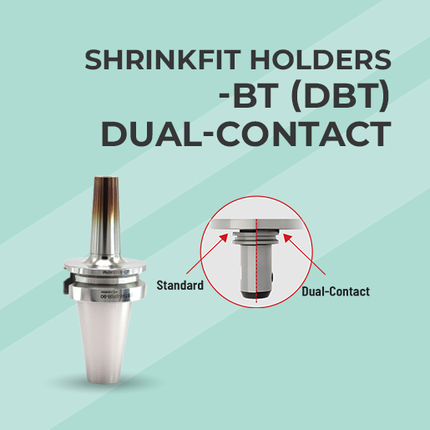

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

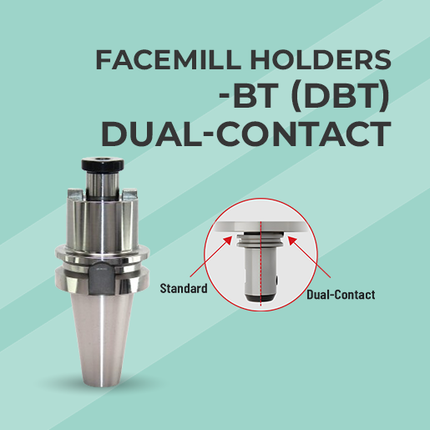

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

- Face Mill Holders-BT Taper

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

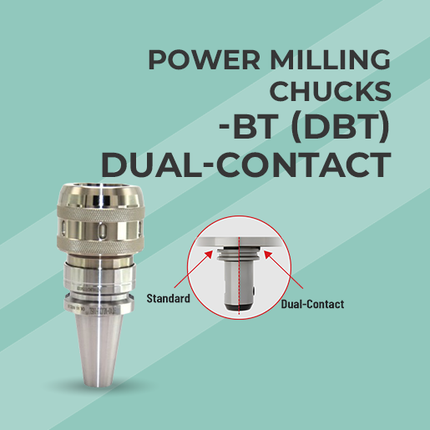

- Power Milling Holders

- Power Milling Holders-CAT Taper

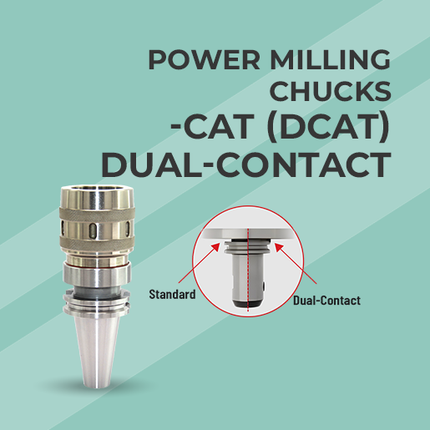

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube