- No products in the cart.

Shrink Fit Holders Supplier & Distributor in USA

Frequently Asked Questions

1. How tight is the grip of a shrink fit holder compared to other tool holders?

PAC Tools Shink fir holders offer an exceptionally tight grip with minimal runout, outperforming traditional collet or end mill holders. This ensures greater precision and rigidity, making PACTools ideal for high-performance machining applications.

2. Is there a risk of damaging the tool shank due to heat?

Yes, excessive heat during machining or improper shrink-fit procedures can potentially damage the tool shank. PACTools recommends using proper cooling and fitting techniques to avoid thermal stress on the tool.

3. What happens if I use an undersized tool shank?

Using an undersized tool shank tool shank can lead to poor clamping, tool slippage, and reduced machinih accuracy. PACTool advices using properly sized shanks to ensure secure fir and optimal performance.

4. How do I know if the tool is fully inserted during the shrink process?

During the shrink process, PAC Tools recommends marking the tool shank beforehand. Once inserted, the mark should align with holder’s face to confirm full and proper insertion.

5. How do I remove a stuck tool from a shrink fit holder?

To remove a stuck tool, reheat the PACTools shrink fit holder using an induction heater. The holder expands thermally, allowing safe and easy removal of the tool without force or damage.

6. Are shrink fit holders balanced for high RPM use?

Yes, Shrink fit holders from PACTools are precisely balanced for high-speed applications, typically up to 25,000 RPM or more. ensuring smooth operation and reduced vibration in high-performance machining operation. for more information contact us at +1 262-282-2456 or email us at

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

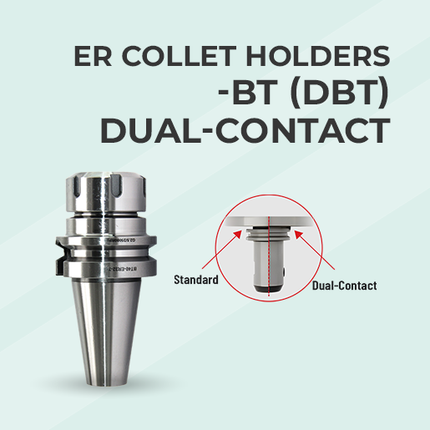

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

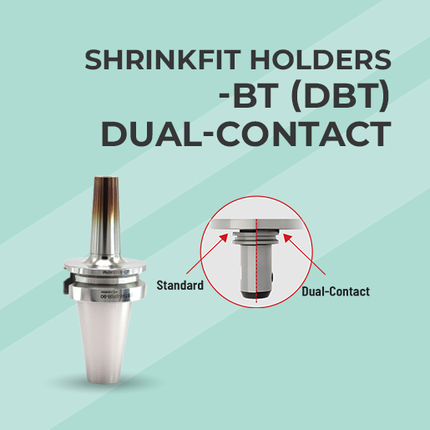

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

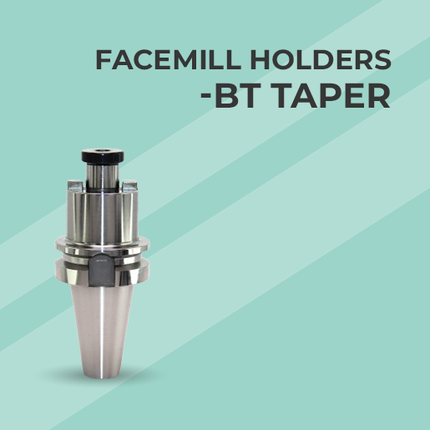

- Face Mill Holders-BT Taper

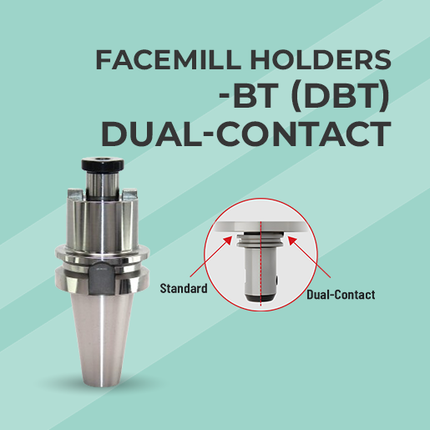

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

- Power Milling Holders

- Power Milling Holders-CAT Taper

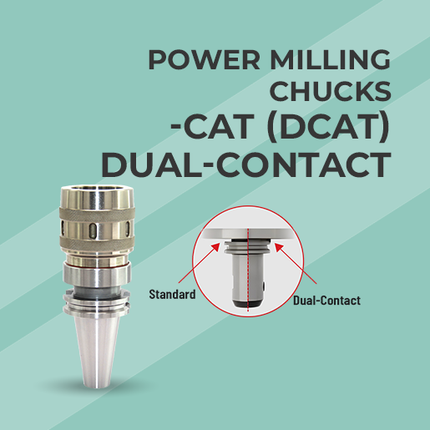

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

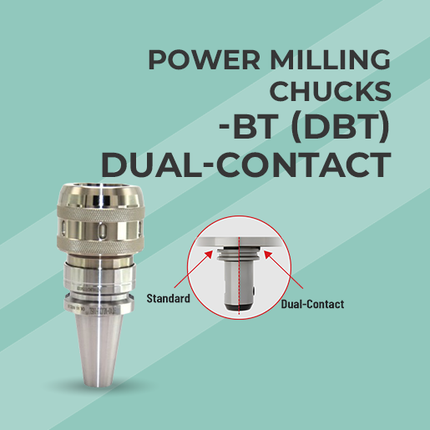

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube