- No products in the cart.

Tool Holders Supplier & Distributor in USA

Frequently Asked Questions

1. What is the difference between single-ended and double-ended holders?

Single-ended holders have one working end, such as an ER16 straight-shank with a mini nut—commonly used for specific tool sizes and applications. Double-ended holders allow tools to be mounted on both ends, offering flexibility for certain setups.

2. How do I choose the correct taper (e.g., CAT, BT, HSK)?

Select the taper based on your CNC machine’s spindle type. For example, use CAT holders with CAT spindles, BT with BT spindles, and HSK for high-speed, high-precision spindles.

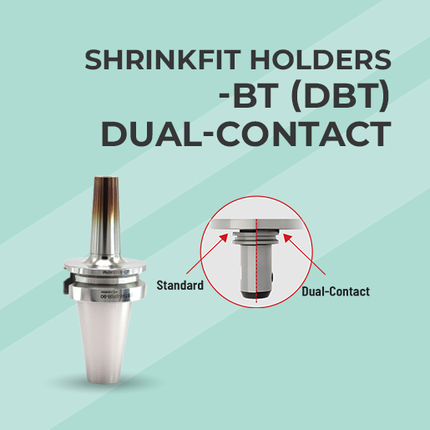

3. When should I use shrink-fit holders?

Shrink-fit holders provide superior concentricity and are ideal for high-speed and high-precision applications where minimal runout is critical. They are compatible with most taper types.

4. What are tool holder bushings?

Bushings (e.g., Type-C, CS, Z, J, B) are adapters that fit inside tool holders to accommodate tools of smaller diameters. For example, a Type-CS bushing can adapt to a 7/8″ bore, allowing flexible tooling options.

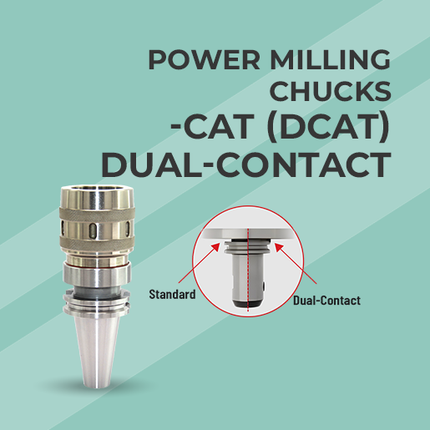

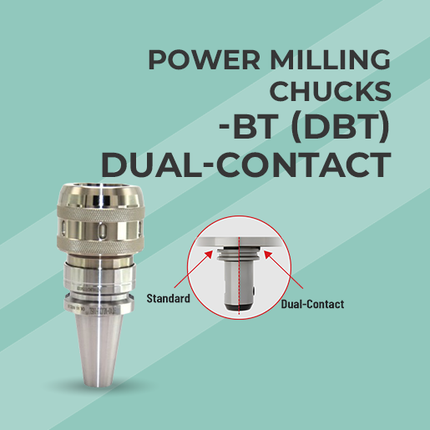

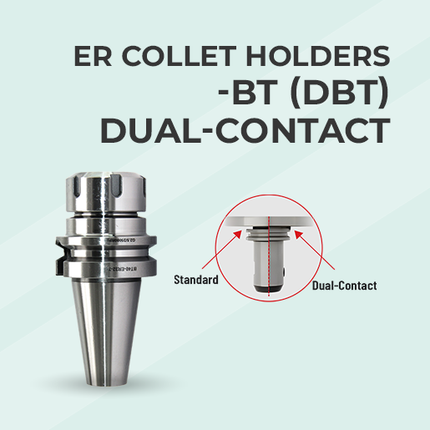

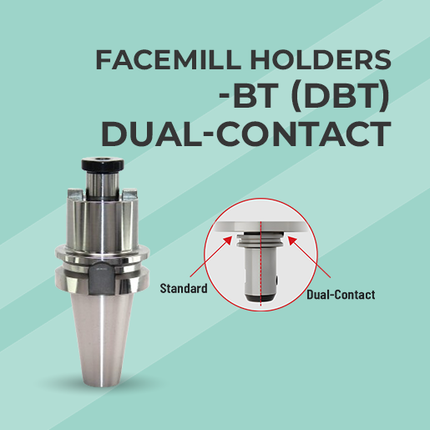

5. Why use dual-contact holders?

Dual-contact holders make contact with both the taper and flange surfaces of the spindle, increasing axial rigidity and accuracy. This reduces vibration and enhances performance during demanding milling operations.

6. What maintenance do tool holders require?

Regularly clean the taper and flange surfaces, especially before tool changes.

Inspect for signs of wear or damage—worn holders can decrease accuracy and damage the spindle.

Replace worn collets promptly, as they are softer and tend to wear out faster than tool holders.

Inspect for signs of wear or damage—worn holders can decrease accuracy and damage the spindle.

Replace worn collets promptly, as they are softer and tend to wear out faster than tool holders.

7. What support does PAC Precision Tools USA provide?

Sales and technical assistance available via phone and email

Access to downloadable product catalogs

Customer-friendly service policies, including shipping, returns, and detailed terms on the official website

Access to downloadable product catalogs

Customer-friendly service policies, including shipping, returns, and detailed terms on the official website

Quick Link

- Tool Holders

- ER Collet Holder

- ER Collet Holders-CAT Taper

- ER Collet Holders-CAT(DCAT) Dual-contact

- ER Collet Holders-BT Taper

- ER Collet Holders-BT(DBT) Dual-contact

- ER Collet Holders-HSK Taper

- ER Collet Holder - HSK Coolant Tube

- End Mill Holders

- End Mill Holders - CAT Taper

- End Mill Holders-CAT(DCAT)Dual-contact

- End Mill Holders-BT Taper

- End Mill Holder-BT(DBT)Dual-contact

- End Mill Holder-HSK Taper

- End Mill Holders-Set Screw And HSK Coolant Tube

- Shrink Fit Holders

- Shrink Fit Holder-CAT Taper

- Shrink Fit Holder-CAT(DCAT)Dual-contact

- Shrink Fit Holder - BT Taper

- Shrink Fit Holder - HSK Taper

- Face Mill Holders

- Face Mill Holders-CAT Taper

- Face Mill Holders-CAT(DCAT)Dual-contact

- Face Mill Holders-BT Taper

- Face Mill Holders-BT(DBT)Dual-contact

- Face Mill Holders-HSK Taper

- Face Mill Holders-Lock Screw and HSK Coolant tube

- Hydraulic Holders

- Hydraulic Holders-CAT Taper

- Hydraulic Holders-BT Taper

- Hydraulic Holders-HSK Taper

- Power Milling Holders

- Power Milling Holders-CAT Taper

- Power Milling Holders-CAT(DCAT)Dual-contact

- Power Milling Holders-BT Taper

- Power Milling Holders-BT(DBT)Dual-contact

- Power Milling Holders-HSK Taper

- Quick Change Tapping Holders

- Quick Change Tapping Holders-CAT Taper

- Quick Change Tapping Holders-BT Holder

- Quick Change Tapping Holders-HSK Taper

- ER Straight Shank Holders

- ER Straight Shank Holders-Single Ended

- ER Straight Shank Holders-Double Ended

- Collets

- ER Collets

- ER Steel Sealed Collets

- ER External Coolan Collet(Jet Spray)

- ER Tap Collets

- ER Tap Steel Sealed Collets

- ER Floating Tap Collet

- DNA(Dead Nuts Accurate) Collets

- SK Collets

- DA Collets

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ(EOC) Collets

- Straight Collets for Milling Chuks

- Quick Change Tapping Adapters(Collets)

- R8 Collets

- 5C Collets

- 16C Collets

- 3J Collets

- Tool Holders Bushings

- Type-C Bushings

- Type-CS Bushings

- Type-Z Bushings

- Type-J Bushings

- Type-B Bushings

- Boring Bar Sleeves

- Retention Knobs

- CAT Retention Knobs

- BT Retention Knobs

- CNC Live/Dead Centers

- CNC Heavy Duty Live Centers

- Interchangeble Heavy Duty Centers

- CNC Small Casing Centers

- Slimline Medium Duty CNC Live Centers

- Dead Centers

- Other Accessories

- ER Nut

- ER Wrench

- Tool Locking Device

- Spindle Wiper

- HSK Coolant Tube